Check-Mate identifies:

- Unbalance

- Off-set misalignment

- Angular misalignment

- Bent shaft

- Looseness

- Unequal foundation stiffness

- Coupling lock-up

- Bearing problems-preload, looseness, inner race, outer race, ball train defects

- Gear defects-tooth wear, misalignment, eccentricity, broken or worn tooth/teeth, hunting tooth faults

- Sub-synchronous bearing instability

- Electrical faults-cracked rotor bars, eccentric rotor

- Rubs-rotor, axial

- Belt problems

- Cavitation

- Oil whirl

- Dry whirl

- Many other problems

In addition, Check-Mate identifies faulty readings caused by a loose or damaged sensor.

Check-Mate analyzes fixed speed, variable speed, or multiple independent speed machinery. The alarm levels are set at specific narrowband frequencies and dynamically change on-the-fly as the machine speed changes.

Unique Features of Check-Mate:

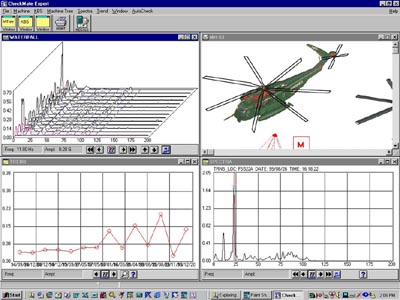

- Check-Mate is model based, object oriented and data driven.

- Models of actual machines are quickly constructed in the computer using icons representing parts such a gears, bearings, shafts , motors etc..

- Spectra are accessed simply by clicking on the measurement locations (represented by a measurement icon).

- Frequencies associated with the 17 types of typical generic faults listed above (called fault frequencies) are easily displayed by clicking on that part's icon. Custom fault frequencies such as resonances and other failure modes can be added by our engineers so that the machine's common fault patterns are loaded into your knowlege base. Sums, differences, side band modulations are simple to add such as the sidebands of gear mesh frequencies that are often associated with pitted, chipped or spalled gears, for example.

- Spectral peaks are quickly identified. By clicking on a spectral peak of interest, the source of this frequency is automatically displayed in a list box. Alternatively the user can go the the part and ask for 1X, 2X, 3X rotation speed or the BPFO (outer race ball pass frequency and multiples to be dispalyed on the current spectra. No more time consuming look up tables. It's all done automatically for you.

- Trends for specific fault frequencies are extracted from waterfall diagrams. These trends will track the actual fault frequencies over a period of time, as the machine speed varies, or across a family of machines.

- Trends will also accurately track harmonics and wide band frequencies for variable speed machinery.

- Alert levels are set for individual fault frequencies, harmonics and wide-band modulations.

- Actual frequencies for alerts are automatically recalculated for machine speed of each spectrum.

- True zoom spectra are accepted.

- Capabilities surpassing envelope or band analysis are achieved with DSA International's Faultrum technology which we define as the spectra of fault frequencies of interest.

- Faultrum technology analyzes and sets alert levels for fault characteristics rather than spectral frequencies, greatly simplifying and improving the accuracy and reliability of fault diagnostics.

- Diagnostics include clear advice on appropriate operation or maintenance actions.

- DSA International will supply customized rules or machine parts to meet your special requirements.

CHECK-MATE SOFTWARE DEMONSTRATION

DSA International has prepared a slide-show presentation of the Check-Mate software. This demonstration is approximately 1.4 Megs. After downloading, double-click on the file. You will have control of the demonstration with the VCR button. It was created in Install Shield and contains an "uninstall" function to free up room on your computer after viewing. DSA International has prepared a slide-show presentation of the Check-Mate software. This demonstration is approximately 1.4 Megs. After downloading, double-click on the file. You will have control of the demonstration with the VCR button. It was created in Install Shield and contains an "uninstall" function to free up room on your computer after viewing.

|